Centrifugal Pumps in Muir, PA

Muir Small Centrifugal Pumps

Centrifugal pumps' high flow rates and capacity to handle large volumes of fluid are two of their main advantages. Additionally, they have a fairly simple design that is simple to maintain. Applications for Centrifugal pumps include water treatment, irrigation, oil & gas production, and chemical processing. Centrifugal pumps come in a variety of designs, including axial, mixed, and radial flow pumps. Each type has its own distinct set of qualities and is created for particular applications.

Practical Applications for Drum Pumps in Muir, PA

- Gasoline production: The oil and gas industry uses drum pumps to transport fluids like oil.

- Manufacturing: Fluids like coolants, lubricants, and cleaning agents are transferred using drum pumps in manufacturing settings.

- Construction: To transport construction materials like concrete and grout, drum pumps can be used.

- Drum pumps are used in power generation facilities, such as nuclear power plants and coal-fired power plants, to move fluids.

- Chemical processing: Drum pumps are used to move chemicals in a range of chemical processing applications, such as the manufacture of personal care products, food processing, and pharmaceuticals.

- Water treatment: In water treatment facilities and other locations where clean water is required, drum pumps are used to move water and other fluids.

- Drum pumps are used in the mining sector to move fluids like chemicals and water.

- Agriculture: Drum pumps are used to deliver water and other fluids to plants and crops.

Drum Pumps in Muir, PA

For transfering and dispensing fluids.

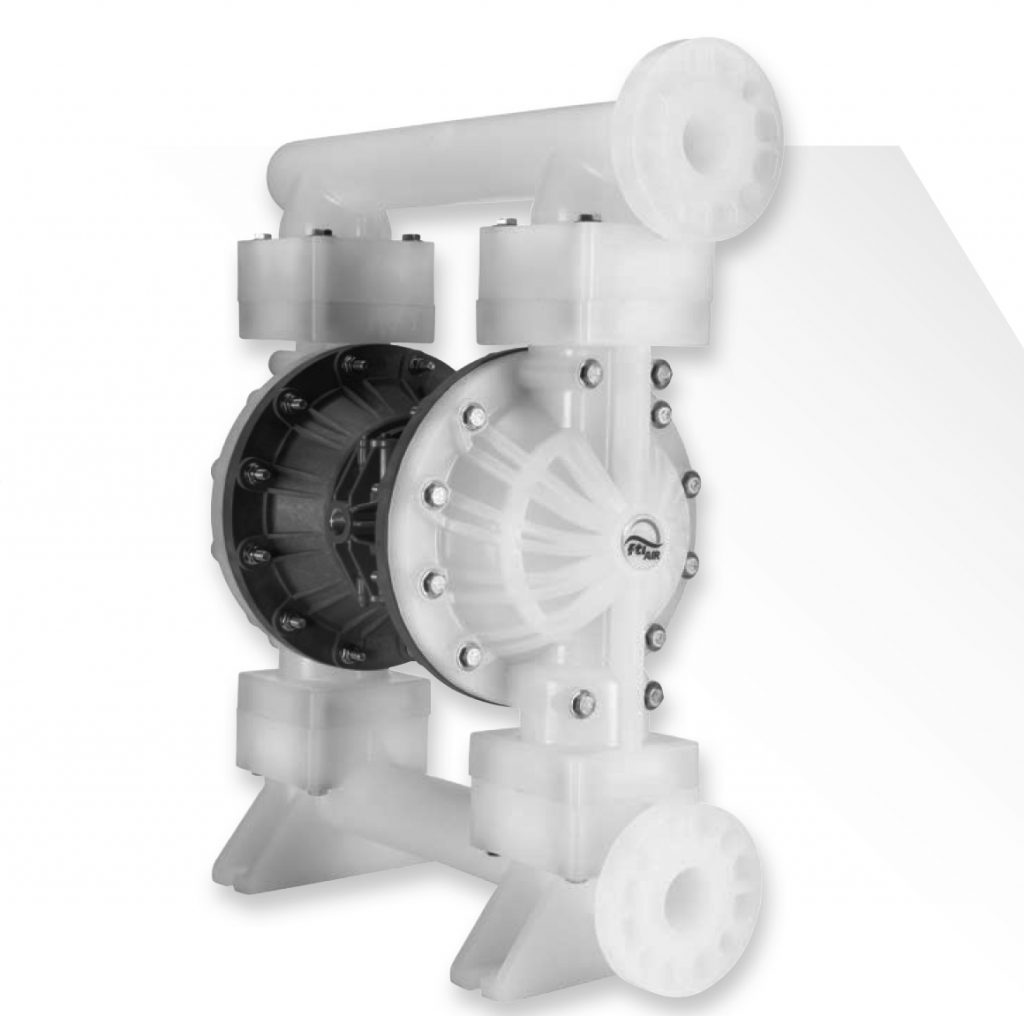

Muir PA Air-Operated Diaphragm Chemical Pumps are Durable, Reliable, and Easy to Maintain

These pumps can move a wide range of chemicals, both acidic and alkaline, reliably and with the least amount of maintenance. Because they are powered by air, they can be used in dangerous places because they can't explode and don't have any electrical parts. Air-Operated Diaphragm Chemical Pumps are long-lasting and reliable pieces of equipment that can be used for a long time in harsh conditions.

Not only do these pumps need little maintenance, but they also have a system of air valves that keeps the flow rate and pressure consistent. They work well to move a wide range of chemicals without the need for priming or lubrication. Air Operated Diaphragm Chemical Pumps are very easy to maintain, making them an ideal choice for many chemical applications.

Practical Applications for Muir Small Centrifugal Pumps

Small Centrifugal pumps have a wide range of uses across varying industries. Examples of practical applications for small Centrifugal pumps include:

- Water treatment: In applications where clean water is required, such as water treatment plants, small Centrifugal pumps are used to move water and other fluids.

- Plumbing: To move water and other fluids in plumbing systems, small Centrifugal pumps are employed.

- Aquariums: To circulate water in aquariums, small Centrifugal pumps are employed.

- Chemical processing: Small Centrifugal pumps are used to move chemicals in a range of chemical processing applications, such as the creation of personal care products, food processing, and pharmaceutical manufacturing.

- HVAC systems: The fluids in heating, ventilation, and air conditioning systems are circulated by small Centrifugal pumps.

- Small Centrifugal pumps are utilized in medical devices like dialysis machines and infusion pumps.

- For irrigation in agriculture, small Centrifugal pumps are employed to deliver water and other fluids to plants and crops.

- Small Centrifugal pumps are used in firefighting applications to move fluids like water and other substances.

- In construction, small Centrifugal pumps are used to move materials like grout, concrete, and other materials.

MSDB SERIES - MAGNETIC DRIVE, SEALLESS, Muir CENTRIFUGAL PUMPS

- High specific gravity handling – over 1.8

- High power neodymium magnetic drive system handles high specific gravity fluids

- Engineered for corrosive fluids with polypropylene/Ryton© or PVDF/Ryton© construction

- Two stage versions contain two impellers, three stage versions contain three impellers

- Sealless design improves reliability with no seal maintenance to perform or seal leaks

- Minimum flow rate is 1 gpm (.23m3/h)

- Heads up to 300 feet (91.5m)

- Horizontal or vertical (with IEC motor only) installation

- Compact close-coupled design

- Maximum working pressure up to 135 PSI (9.3 bar)