Gunnison, UT Drum Pumps

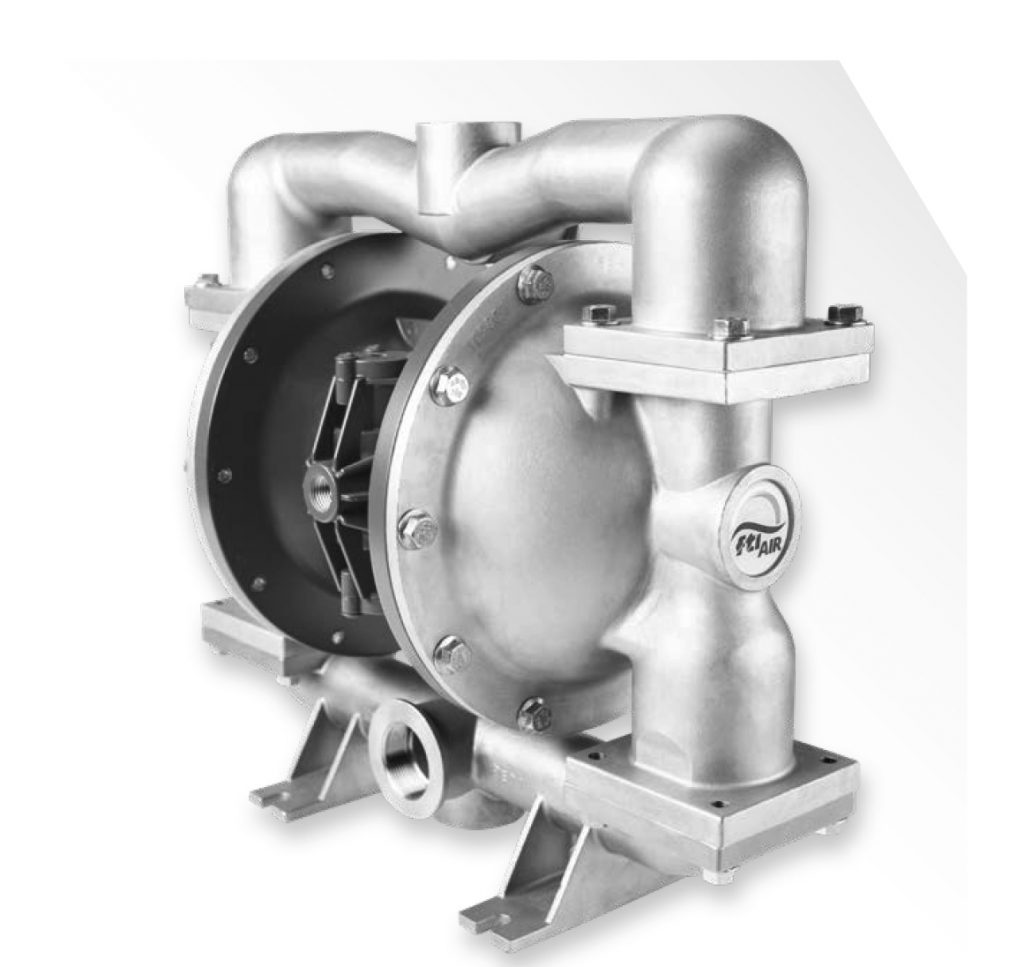

Gunnison UT Air-Operated Diaphragm Chemical Pumps are Durable, Reliable, and Easy to Maintain

These pumps can move a wide range of chemicals, both acidic and alkaline, reliably and with the least amount of maintenance. Because they are powered by air, they can be used in dangerous places because they can't explode and don't have any electrical parts. Air-Operated Diaphragm Chemical Pumps are long-lasting and reliable pieces of equipment that can be used for a long time in harsh conditions.

Not only do these pumps need little maintenance, but they also have a system of air valves that keeps the flow rate and pressure consistent. They work well to move a wide range of chemicals without the need for priming or lubrication. Air Operated Diaphragm Chemical Pumps are very easy to maintain, making them an ideal choice for many chemical applications.

Gunnison UT Drum Pumps

Drum pumps are utilized for a variety of industrial, commercial, and residential purposes that all entail transferring liquids from sizable drums or containers to other places where the liquid is needed. This involves moving liquids like water, oil, gasoline, and a variety of other kinds of chemicals. Drum pumps are useful for filling containers and for use in manufacturing because they can dispense fluids in precise volumes.

Drum pumps are widely used in a variety of sectors, including industrial, agriculture, and mining. Drum pumps are used in chemical processing businesses for things like food processing and pharmaceuticals. Drums are a common container in the water treatment and construction sectors, hence these businesses also employ drum pumps.

Gunnison Small Centrifugal Pumps

Centrifugal pumps' high flow rates and capacity to handle large volumes of fluid are two of their main advantages. Additionally, they have a fairly simple design that is simple to maintain. Applications for Centrifugal pumps include water treatment, irrigation, oil & gas production, and chemical processing. Centrifugal pumps come in a variety of designs, including axial, mixed, and radial flow pumps. Each type has its own distinct set of qualities and is created for particular applications.

Gunnison, UT Drum Pump Accessories

- Liquid Level Control - The FTI Liquid Level Control is a pneumatic/mechanical device that will automatically turn the pump on and off as the liquid level changes

- Cycle Counter - The FTI Air Cycle Counter is an electronic device that counts pump cycles by detecting the presence of the valve carrier. The cycle counter can be universally used on any new or existing FTI Air pump with the proper air valve components.

- Pulsation Dampeners - Removes virtually all hydraulic shock while producing a near steady flow of fluid. Protect piping, valves and fittings from destructive pulsations and surges. Available in a wide range of materials of construction

- AODDampener - AODDampener is unique pulsation dampener manufactured from 316L stainless steel with PTFE backed diaphragm, has fully automatic air control and handles a wide variety of applications.

- SPILLSTOP - Fully pneumatic system safely captures leaked product due to diaphragm failure and automatically shuts down failed pumps to eliminate costly product loss and prevent hazardous spills.

- Filter/Regulator - Compact, integrated design saves space and reduces piping, includes dual scale psi/Bar gage. Filters incoming air to five microns. Regulator adjusts air pressure from 7.3 to 120 psi (.5 to 8.3 bar).

Small Centrifugal Pumps in Gunnison, UT

High flow rates and capacity to handle large volumes of fluid!

Gunnison, UT Air-Operated Diaphragm Chemical Pumps and Their Applications

An Air Operated Diaphragm Chemical Pump is a type of positive displacement pump that uses a combination of compressed air and an elastic diaphragm to move chemical liquids. This type of pump is often used in industrial settings, such as chemical processing plants and water treatment facilities, due to its ability to handle high flow rates and corrosive materials. It’s also known for its superior design, as it can run dry without causing damage, making it more reliable than other types of pumps.

These pumps are highly versatile and have a wide range of applications. They are often used in the chemical, pharmaceutical, and food industries, as well as in industrial, agricultural, and water treatment operations. Air Operated Diaphragm Chemical Pumps can be used to transfer, meter, or dispense low to high-viscosity fluids and chemicals while providing precise, accurate flow rates with minimal maintenance.